Vacuum Ejectors

Showing 1–12 of 16 results

AVAC Vakuumteknik offers a variety of vacuum ejectors and solutions where vacuum is a part of the technical outcome, such as lifting. Choose between our different ejectors – multi function ejectors, multi circuit ejectors, base ejectors, solenoid valve operated ejectors or ejectors with vacuum holding valve.

Are you looking for something else? Contact us and we will help you develop a solution that fits your need.

-

2BV AIR SAVE

-

Air operated blow-off

-

AUTOVAC

-

Autovac MFE

-

Ejector 2BV

-

Ejector Booster Release

-

Ejector BVX

-

Ejector INLINE

-

Ejector MINI

-

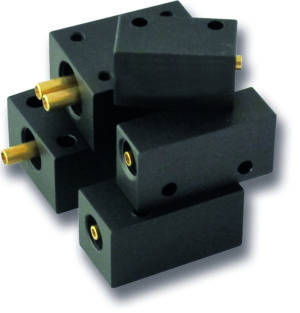

Ejector MV

-

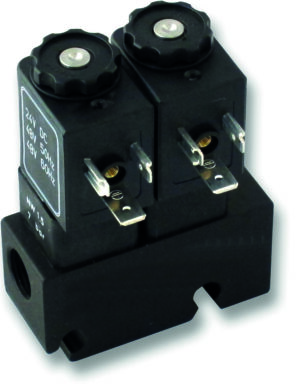

Ejector MV-MV

-

Ejector Original